In some papers it was reported that flash sintering allows to densify ceramics 3ysz batio 3 bifeo 3 al 2 o 3 mgal 2 o 4 8ysz hydroxyapatite gdc 51 57 58 with nanometric grains.

Flash sintering of ceramics.

Flash sintering is not the first sintering route developed for ceramics which uses electric field to enhance sintering rates.

Prof richard i todd.

1 1 sintering of ceramics ceramics are inorganic non metallic materials characterized by unique combination of physical mechanical.

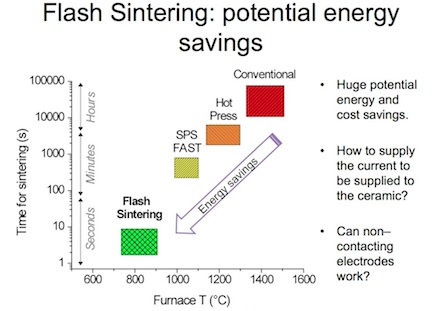

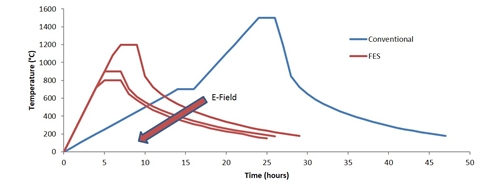

Flash sintering is a novel densification technology for ceramics which allows a dramatic reduction of processing time and temperature.

Discovered by cologna et al.

In 2010 flash sintering utilizes the non equilibrium rise in current under applied electric field to densify ceramic green body compacts in seconds.

Normally it takes several hours at a temperature well in excess of 1000 c to sinter a ceramic.

Flash sintering is an electrical field assisted consolidation technology and represents a very novel technique for producing ceramic materials which allows to decrease sensibly both processing temperature.

Microwave sintering uses microwave frequency ca 300 mhz 300 ghz electromagnetic radiation to sinter ceramic materials at temperatures below conventional sintering temperatures and in short sintering times 58.

However it has recently been discovered that this can be achieved in a few seconds with much lower furnace temperatures by applying an electric current to the specimen.

Sglavo graphite creep negation during flash spark plasma sintering under temperatures close to 2000 c charles manière et al marco cologna this content was downloaded from ip address 207 46 13 22 on 20 06 2020 at 16 00.

Flash sintering of ceramics.

Flash sintering occurs when an electrical potential difference is applied across a ceramic powder compact and is characterised by an electrical power surge at a specific combination of electric.

Since the first publication on flash sintered zirconia 3ysz in 2010 it has been intensively researched and applied to a wide range of materials.

The lower sintering time and temperature used in flash sintering have other beneficial effects associated with the sintered body microstructure.

Flash sintering fs is an energy efficient sintering technique involving electrical joule heating which allows very rapid densification 60 s of particulate materials.

Flash sintering of ceramics.

Description flash sintering fs has been the subject of intense study by the ceramics community in recent years.

It represents a promising sintering route to reduce economic energetic and environmental costs associated to firing.